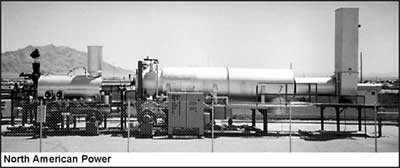

Applied Microbiological Services (AMS)has been a leader in finding solutions for testing and environmental concerns for over two decades. Helping to determine viable alternatives to handling medical waste has been an area of great success for the AMS.Las Vegas-based North American Power Company manufactures the Thermal Recovery Unit, which comes in two models that utilize the pyrolysis method. The recovery unit is approved by the State of California’s Department of Health Services as an alternative treatment technology for the destruction of medical waste. Creation of the testing protocol, and subsequent analysis, was performed by Applied Microbiological Services (AMSLABS.COM), of Long Beach, California.

“The machine formally degrades any organic material that is introduced into the process. The resulting product is reduced by an average 85 to 95 percent in weight and volume. The resulting carbon char – we have not found a case where it has not been – is sterile, non-leachable, non-hazardous and can be thrown away in a landfill or used for other purposes”, says Ed Stammel, NAPC’s founder.

The heat generated from the destruction process can be recovered and used to provide energy. “You can run it through a steam turbine process,” says Stammel. “It can be used anywhere there is a need, whether it be for drying, energy production, heating and hydroponics. We have a client that will be using the equipment for its very large-scale MSW plant.”

United Recycling Technology Inc., a Nevada corporation with offices in Los Angeles founded in 2001 by Aram Sarkissian, is currently in the process of selecting a site to house its Medical Waste Gasification Process unit. This process has also received certification from the state, and the protocol creation, and subsequent testing, was also performed by Applied Microbiological Services (AMSLABS.COM), of Long Beach, California.

“The unit has already been tested and is ready to run,” says Sarkissian, the president of the company. “On average, you are looking at about a 90 percent reduction in weight and volume. Everything turns into a silicon carbon ash substance. A major advantage is the reduction of the cradle-to-grave liability, as opposed to an autoclave that will only disinfect. After the process of an autoclave, the material is usually shredded, placed in a compactor and then discarded in a landfill. As well, our system has no additional emission controls that are required.”

In addition to being able to handle all varieties of medical waste, the excess energy created by the process will be recycled. “We can take the gasses, run them in our burners and save on gas,” says Sarkissian. “The system can be self-running.”

1. Jan 2006, PEAT International newsletter online PEAT.COM